How Are Telescopes Made?

Telescopes have been instrumental in expanding our understanding of the universe, allowing us to peer into the depths of space and time. The process of making a telescope is a fascinating blend of science, engineering, and craftsmanship. This article will delve into the intricate steps involved in the creation of telescopes, from the initial design to the final assembly, and will address some common questions and practical considerations for those interested in the subject.

The Basics of Telescope Design

Before diving into the manufacturing process, it's essential to understand the basic components and types of telescopes. There are primarily two types of telescopes: refracting telescopes (refractors) and reflecting telescopes (reflectors).

1. Refracting Telescopes: These use lenses to bend (refract) light to a focal point. The main components include the objective lens and the eyepiece.

2. Reflecting Telescopes: These use mirrors to reflect light to a focal point. The primary components are the primary mirror, secondary mirror, and the eyepiece.

Step-by-Step Process of Making a Telescope

1. Designing the Telescope

The first step in making a telescope is the design phase. This involves determining the type of telescope, its intended use (e.g., amateur stargazing, professional astronomy), and the specifications such as aperture size, focal length, and magnification.

- Aperture: The diameter of the primary lens or mirror, which determines the amount of light the telescope can gather.

- Focal Length: The distance between the primary lens/mirror and the focal point, affecting the magnification and field of view.

- Magnification: Determined by the focal lengths of the objective lens/mirror and the eyepiece.

2. Selecting Materials

The choice of materials is crucial for the performance and durability of the telescope. Common materials include:

- Glass: High-quality optical glass is used for lenses and mirrors. Types of glass include crown glass and flint glass, each with different refractive properties.

- Metal: Aluminum or steel is often used for the telescope tube and mount due to their strength and lightweight properties.

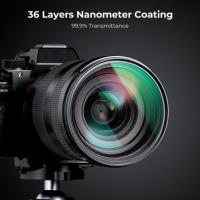

- Coatings: Anti-reflective coatings are applied to lenses and mirrors to enhance light transmission and reduce glare.

3. Fabricating the Optics

The heart of any telescope is its optics. The process of fabricating lenses and mirrors involves several meticulous steps:

- Grinding: The glass is ground to the desired shape using abrasive materials. For mirrors, this involves creating a concave surface.

- Polishing: The ground glass is polished to a smooth finish, removing any imperfections that could distort the image.

- Figuring: This is the final shaping of the lens or mirror to achieve the precise curvature needed for optimal performance.

- Coating: A reflective or anti-reflective coating is applied to enhance the optical properties. For mirrors, a thin layer of aluminum or silver is often used.

4. Assembling the Telescope

Once the optics are ready, the next step is assembling the telescope. This involves:

- Mounting the Optics: The lenses or mirrors are carefully mounted in the telescope tube. This requires precise alignment to ensure the light is correctly focused.

- Constructing the Tube: The telescope tube houses the optics and keeps them aligned. It must be sturdy and free from vibrations.

- Adding the Eyepiece: The eyepiece is installed at the focal point of the telescope. Different eyepieces can be used to achieve various magnifications.

- Mounting the Telescope: The telescope is mounted on a stable base, which can be a simple tripod or a more complex equatorial mount for tracking celestial objects.

5. Testing and Calibration

After assembly, the telescope undergoes rigorous testing and calibration to ensure it performs as expected. This includes:

- Optical Testing: Checking for aberrations, distortions, and alignment issues.

- Mechanical Testing: Ensuring the stability and smooth operation of the mount and focusing mechanisms.

- Field Testing: Observing celestial objects to verify the telescope's performance in real-world conditions.

Practical Considerations and Common Questions

How Long Does It Take to Make a Telescope?

The time required to make a telescope can vary widely depending on its complexity and the level of craftsmanship involved. A simple amateur telescope might take a few weeks to a few months to complete, while professional observatory telescopes can take several years.

Can I Make a Telescope at Home?

Yes, many amateur astronomers build their own telescopes. Kits are available that provide the necessary materials and instructions. However, making a high-quality telescope requires precision and patience, especially in grinding and polishing the optics.

What Are the Costs Involved?

The cost of making a telescope depends on the materials and components used. A basic amateur telescope can cost a few hundred dollars, while professional-grade telescopes can run into thousands or even millions of dollars.

How Do I Maintain a Telescope?

Proper maintenance is crucial for the longevity and performance of a telescope. This includes:

- Cleaning the Optics: Using appropriate cleaning solutions and techniques to avoid scratching the lenses or mirrors.

- Protecting from Dust and Moisture: Storing the telescope in a dry, dust-free environment.

- Regular Calibration: Periodically checking and adjusting the alignment of the optics.

The process of making a telescope is a remarkable journey that combines scientific principles with meticulous craftsmanship. Whether you're an amateur astronomer looking to build your own telescope or simply curious about how these incredible instruments are made, understanding the steps involved can deepen your appreciation for the art and science of telescope making. From the initial design and material selection to the precise fabrication of optics and final assembly, each step is crucial in creating a tool that allows us to explore the wonders of the universe.